Sticking with the Eurofighter theme (I used to work on the real aircraft HUD at BAE Systems, so it has a place in my heart) I decided to up the anti with the second variant.

This model is based on the 'RC Powers' Eurofighter plans with some modifications based on my brief experience with v1.0 - sadly now flying around the great model shop in the sky.

I've improved access to the huge fuselage enclosure for hassle free alterations to the avionics which will make things much easier in the field when I start experimenting with the airframe. I've also made a lot of reinforcement to the parts, and therefore weight - notice the carbon spar that also forms the leading edge for the tail fin. To overcome added weight I am going to streamline the airframe as much as possible with coverings and chamfers to reduce drag - the propeller will also be selected to give me acceleration over top speed.

Everything will be built with maintenance, durability and adaptability in mind as I do intend to keep this aircraft flying for as long as possible - the big goal is to use it's large body to house an autopilot !

Tuesday, 8 April 2014

Sunday, 30 March 2014

RIP version 1.0

Succumb to physics and poor piloting skills, too fast in a dive and couldn't pull out.

Ideally I should have pulled back on the throttle but the limited control throws and flexible foam control surfaces didn't help.

Succumb to physics and poor piloting skills, too fast in a dive and couldn't pull out.

Ideally I should have pulled back on the throttle but the limited control throws and flexible foam control surfaces didn't help.

I decided not to resurrect it even though it was fully repairable because it's now served it's purpose about how easy these depron planes fly. Next step is a more scale approach with the following design upgrades :

- Faster motor for more thrust.

The scale approach will add much more drag and therefore needs more punch to keep in going. - Easy, 1x touch interchangeable motor.

For trailing multiple power plants and props.

- Rigid construction.

More use of carbon fibre, balsa and coverings to support the depron frame to increase strength and control surface rigidity. Control surfaces are also going to be made from stronger materials.

- Uprated electronics and controls.

Installation of UBEC to provide power if the speed controller fails.

Metal geared servos for precise control.

Option to be gyro stabilised. - Control surfaces.

As fore mentioned these are going to be much stiffer and include a full rudder and developed working canard control. - Use of developed KF aerofoil.

Transit from flate plate, to KF4 in order to understand the impact on the model's flight performance.

- Large, unhindered and quick change internal carrying capacity.

Ability to easily change the CG and install components such as auto pilot, and cameras / sensors.

Thursday, 27 March 2014

Wing Trials...

Playing around with the Horton wing today and wondered if I could skin the aerofoil instead of using a KF foil. My drama with the KF is that the Horton wing is quite narrow, too many steps in the foil will cause a lot of drag and also interfere with the control surfaces.

A flying wing must have the centre of gravity and turning moment infront of the main body of lift to maintain stability. This causes a nose down attitude, therefore most wings have a slight 'up elevon' control to keep the tail down and the wing level. The Hortons used a reflexed aerofoil shape which is a lot more efficient.

My concern with the KF foil wing was that the coarse steps would interfere with the control surfaces too much and require them to be overly large and therefore too twitchy to control whilst causing un-necessary drag.

As can be seen below, by adding a simple balsa spar at 30% chord, a 3mm sheet of depron can be forced over the plan and create a near perfect reflexed and semi-symmetrical aerofoil - this is something I am definitely going to persue over the KF foil !

Wednesday, 26 March 2014

Stage 1 - Preliminaries...

This will be my first flying wing, it's primary function is to act as a test bed for development. There are a few types of flying wing platform to chose from, I have decided to go for the swept wing as it mirrors the Horton's aircraft but also I believe it is the easier and most aesthetic one to use.

Next thing to consider is construction. I want simplicity and ease of repair / modification and the only aerofoil to use here is the KF (Kline–Fogleman) type that uses a series of steps in the basic form to create a rudimentary aerofoil shape. These are idea for small, light model aircraft as they word well and are extremely easy to make.

The shape I am opting for is a KFm-3, this type gives me a nice thick wing to play with with a decent shape. It is non symmetrical because I have no intention to do full aerobatics, but the lower section should help flow around the leading edge during pitch up.

Power will be from a centre 6" pushing propeller, and the control will be from 2x mixed elevons. These elevons will have a slight upward angle to provide a level of effective 'washout' to the wing. This is essential to maintain control of the wing in the event of a deep stall and on landing.

Because fine control is needed with a flying wing, a fair bit of reinforcement will be employed...

Flying wing design...

I've always been fascinated by pre World War 2 designs that were carried out by Russian and German aviators of the time. I am a big aerodynamics, delta wing and efficiency enthusiast - so one simply cannot ignore the Horton brothers, who to my mind did something as incredible as the Wright brother's first flight.

In 1933 they became synonymous with the flying wing, an aircraft with no fuselage, tail or rudder - just a wing. The idea was to make an efficient glider, so they came up with the concept of removing anything on the aircraft that did not contribute to lift, this cuts down drag by a large degree making for a better glider.

In order to do this the wing has to be perfectly balanced and controlled, something that wasn't easy without complex calculations and systems for the time. However it was achieved by using an unconventional swept back wing and shaping of the wing aerofoil to create a stable craft.

The sweep allowed for some directional stability now the conventional rudder had been removed, and the due to the wing angle, the control surfaces were sufficiently aft of the centre of gravity to be a useful pitching moment (negating the need for the tail section).

Just before the war's end in 1945, the Horton 229 was the first jet powered flying wing and could have been very influential had it entered service, not only was it fast and long ranged, but it's radar cross section / signature was low - the Hortons had unwittingly also created the first stealth aircraft !

The prototype was captured by American soldiers and taken stateside after the war, it is largely though to have been used along with Jack Northrop's designs as the basis for the B-2 Spirit bomber.

With the need for more efficiency and less pollution pushing aircraft design, I can see this sort of thing being developed more and more, something that has largely only been possible due to the advent of advanced computer control for the complex flight surfaces.

This is my homage to the fathers of the flying wing...

In 1933 they became synonymous with the flying wing, an aircraft with no fuselage, tail or rudder - just a wing. The idea was to make an efficient glider, so they came up with the concept of removing anything on the aircraft that did not contribute to lift, this cuts down drag by a large degree making for a better glider.

In order to do this the wing has to be perfectly balanced and controlled, something that wasn't easy without complex calculations and systems for the time. However it was achieved by using an unconventional swept back wing and shaping of the wing aerofoil to create a stable craft.

The sweep allowed for some directional stability now the conventional rudder had been removed, and the due to the wing angle, the control surfaces were sufficiently aft of the centre of gravity to be a useful pitching moment (negating the need for the tail section).

Just before the war's end in 1945, the Horton 229 was the first jet powered flying wing and could have been very influential had it entered service, not only was it fast and long ranged, but it's radar cross section / signature was low - the Hortons had unwittingly also created the first stealth aircraft !

The prototype was captured by American soldiers and taken stateside after the war, it is largely though to have been used along with Jack Northrop's designs as the basis for the B-2 Spirit bomber.

With the need for more efficiency and less pollution pushing aircraft design, I can see this sort of thing being developed more and more, something that has largely only been possible due to the advent of advanced computer control for the complex flight surfaces.

This is my homage to the fathers of the flying wing...

Sunday, 16 March 2014

Derpon Eurofighter, first flight...

It's a simple profile parkjet made from 6mm depron foam and all in all cost about £50 to make.

What's nice is this is the first scratch built plane I have ever made, and it flies beautifully.

Flight videos :

Some photos :

Essentials :

1500kv motor and 6x5 propeller running from an 11.1V LiPo

Aerofoil is a simple flat plate at a slight positive angle of attack

As a basic fun jet it flies very stable and predictable, however the power : weight ratio is about 75% what it should be, and the control surfaces are not man enough to turn this aircraft sufficiently. This is partly because depron foam is only semi-rigid and warping occurs when large control throws are input.

Clearly the aircraft needs more power as it just cannot complete a loop without entering deep stall. The control surfaces also need to be of wooden construction in my opinion for sharper control, other than that it is spot on for gentle park flying.

Version 2 will have a lot of extra modifications !

Tuesday, 18 February 2014

Turbo Compressor Maps

The GT3 Esprit uses the following Turbo :

Lotus P/N - A920E6002

Garrett P/N - 465133-(000)3

From the turbo's ID plate, it is known that the GT3 has a 50 trim compressor wheel in a T3 housing. With that information, the compressor 'map' can be obtained from the manufacturer to observe it's performance.

The 'map' is an area graph, covering a complex set of variables, the main culprit being the constantly changing heat generated by compressing air. This is represented by the coloured efficiency 'islands' - the more efficient areas the turbo operates in, the less heat is generated. In the above case, the T3 is actually pretty good across the board, only deviating 65%-75% over the map.

Pressure Ratio.

The Pressure Ratio (PR) can be basically defined as the boost pressure. This turbo's maximum boost pressure on the GT3 Esprit is capped at 0.97 bar (14.06 psi) above atmospheric pressure. Pressure ratio is the absolute pressure at the turbo outlet, divided by the absolute inlet pressure, in this case the pressure ratio = (14.06 psi + 14.7 psi) / 14.7 psi = 1.95

However, no induction system can ever be perfect and will always encounter losses. Whilst the pressure ratio is regulated at 1.95 at the cylinder head, the pressure ratio measured at the turbo outlet itself would be read higher due to these losses, in this example 5% loss gives a PR of 2.05 at the turbo. This represents the fact the turbo has to spin faster to generate the required PR minus the losses.

Therefore, if the engine requires 15lbs of air / minute, it can be seen that the turbo would need to spin faster (by a few thousand rpm) to generate the same air flow.

This clearly sets out the case for an efficient induction system which would reduce turbo spool time (lag) and temperature.

Air Flow.

Air flow rate is rated in pounds of air delivered / per minute (lbs/min), but can also be expressed as cubic feet per minute (cfm).

The graph now shows the approximate air consumption rates for engine speeds of the GT3's 1997cc engine at 3,000 and 6,000 rpm. As can be seen at 3,000 engine rpm, the turbo needs to spin about 116,000 rpm to achieve the demanded pressure ratio. If the induction was more efficient it would need to spin less fast.

At 6,000 engine rpm, the turbo races at nearly 140,000 rpm to maintain the pressure ratio.

Surge Limit.

The last part of the graph is the surge limit line. This dictates how quickly the turbo may accelerate before the blades on the compressor start to encounter turbulence and potentially stall. This can cause the compressor catastrophic damage so it is important to consider this especially as some smaller turbos can accelerate very quickly unless checked.

At idle the engine needs only approximately 4 lbs of air a minute. If the accelerator is smashed, the engine will bolt and the turbo will accelerate and rapidly build up pressure towards the cap point. This rate of acceleration can be contained by the car's ECU, and indeed the Esprit uses a special valve to control this performance called the 'wastegate solenoid'.

Lotus P/N - A920E6002

Garrett P/N - 465133-(000)3

From the turbo's ID plate, it is known that the GT3 has a 50 trim compressor wheel in a T3 housing. With that information, the compressor 'map' can be obtained from the manufacturer to observe it's performance.

The 'map' is an area graph, covering a complex set of variables, the main culprit being the constantly changing heat generated by compressing air. This is represented by the coloured efficiency 'islands' - the more efficient areas the turbo operates in, the less heat is generated. In the above case, the T3 is actually pretty good across the board, only deviating 65%-75% over the map.

Pressure Ratio.

The Pressure Ratio (PR) can be basically defined as the boost pressure. This turbo's maximum boost pressure on the GT3 Esprit is capped at 0.97 bar (14.06 psi) above atmospheric pressure. Pressure ratio is the absolute pressure at the turbo outlet, divided by the absolute inlet pressure, in this case the pressure ratio = (14.06 psi + 14.7 psi) / 14.7 psi = 1.95

However, no induction system can ever be perfect and will always encounter losses. Whilst the pressure ratio is regulated at 1.95 at the cylinder head, the pressure ratio measured at the turbo outlet itself would be read higher due to these losses, in this example 5% loss gives a PR of 2.05 at the turbo. This represents the fact the turbo has to spin faster to generate the required PR minus the losses.

Therefore, if the engine requires 15lbs of air / minute, it can be seen that the turbo would need to spin faster (by a few thousand rpm) to generate the same air flow.

This clearly sets out the case for an efficient induction system which would reduce turbo spool time (lag) and temperature.

Air Flow.

Air flow rate is rated in pounds of air delivered / per minute (lbs/min), but can also be expressed as cubic feet per minute (cfm).

The graph now shows the approximate air consumption rates for engine speeds of the GT3's 1997cc engine at 3,000 and 6,000 rpm. As can be seen at 3,000 engine rpm, the turbo needs to spin about 116,000 rpm to achieve the demanded pressure ratio. If the induction was more efficient it would need to spin less fast.

At 6,000 engine rpm, the turbo races at nearly 140,000 rpm to maintain the pressure ratio.

Surge Limit.

The last part of the graph is the surge limit line. This dictates how quickly the turbo may accelerate before the blades on the compressor start to encounter turbulence and potentially stall. This can cause the compressor catastrophic damage so it is important to consider this especially as some smaller turbos can accelerate very quickly unless checked.

At idle the engine needs only approximately 4 lbs of air a minute. If the accelerator is smashed, the engine will bolt and the turbo will accelerate and rapidly build up pressure towards the cap point. This rate of acceleration can be contained by the car's ECU, and indeed the Esprit uses a special valve to control this performance called the 'wastegate solenoid'.

Spectrum gets an upgrade

Before all the parts can come together the Pi has to be fitted to the case of the Spectrum so that everything can be located and engineered into place correctly.

The ruling element here was the HDMI socket. This was going to be the hardest part to remove if it came to that due to the amount of fine pitch surface mount pins. I do have the equipment to do this but the way I see it, why make life hard ?

The solution was to mount it so that the HDMI was sat near to one of the cut outs already in the Spectrum case. This location also allowed me to keep the ethernet port fixed to the board. The less that could be de-soldered the less likely any damage would occur to the Pi itself.

In order for the Pi to fit in this location of the case a few additional components had to be removed. The audio jack and composite video plug are pretty useless so they went straight away. The twin stack USB port had to be remove as it was too high, this will be replaced by a USB hub at a later date.

The GPIO (general purpose in/out) port also had to go, interestingly the Spectrum had a very similar expansion slot which protruded out of the back so the idea here was to emulate that with this build using a ribbon connector to extend the Pi's GPIO, again at a later date.

The Pi is held in by 2x counter sunk screws into the case with a small stand off. I also added a small heat sink for the CPU/GPU/RAM chip for good measure. Note the Pi will not be powered by the micro USB port in the bottom left, this is because it will interfere with the case screws. Therefore the 5V power will come in via a fuse into test points TP1 and TP2, I fitted two pins onto these locations for the power wires fitted later.

The hole in the back of the case was slightly enlarged to accommodate the HDMI port and the whole thing is ready to be test assembled.

The ruling element here was the HDMI socket. This was going to be the hardest part to remove if it came to that due to the amount of fine pitch surface mount pins. I do have the equipment to do this but the way I see it, why make life hard ?

The solution was to mount it so that the HDMI was sat near to one of the cut outs already in the Spectrum case. This location also allowed me to keep the ethernet port fixed to the board. The less that could be de-soldered the less likely any damage would occur to the Pi itself.

In order for the Pi to fit in this location of the case a few additional components had to be removed. The audio jack and composite video plug are pretty useless so they went straight away. The twin stack USB port had to be remove as it was too high, this will be replaced by a USB hub at a later date.

The GPIO (general purpose in/out) port also had to go, interestingly the Spectrum had a very similar expansion slot which protruded out of the back so the idea here was to emulate that with this build using a ribbon connector to extend the Pi's GPIO, again at a later date.

The Pi is held in by 2x counter sunk screws into the case with a small stand off. I also added a small heat sink for the CPU/GPU/RAM chip for good measure. Note the Pi will not be powered by the micro USB port in the bottom left, this is because it will interfere with the case screws. Therefore the 5V power will come in via a fuse into test points TP1 and TP2, I fitted two pins onto these locations for the power wires fitted later.

The hole in the back of the case was slightly enlarged to accommodate the HDMI port and the whole thing is ready to be test assembled.

Friday, 14 February 2014

New PC case design

Time to make a decent PC case, the old rig has been hanging on the wall for too long. I took some inspiration from the internet and decided on a design that would allow open planning and futuristic look. Initially I wanted a 'Steam Punk' rig but I took this idea from some architecture in Valve's game "Portal" and infrastructure I've seen at McLaren cars factory.

--CAD pic ----

--CAD pic ----

Thursday, 13 February 2014

Wednesday, 5 February 2014

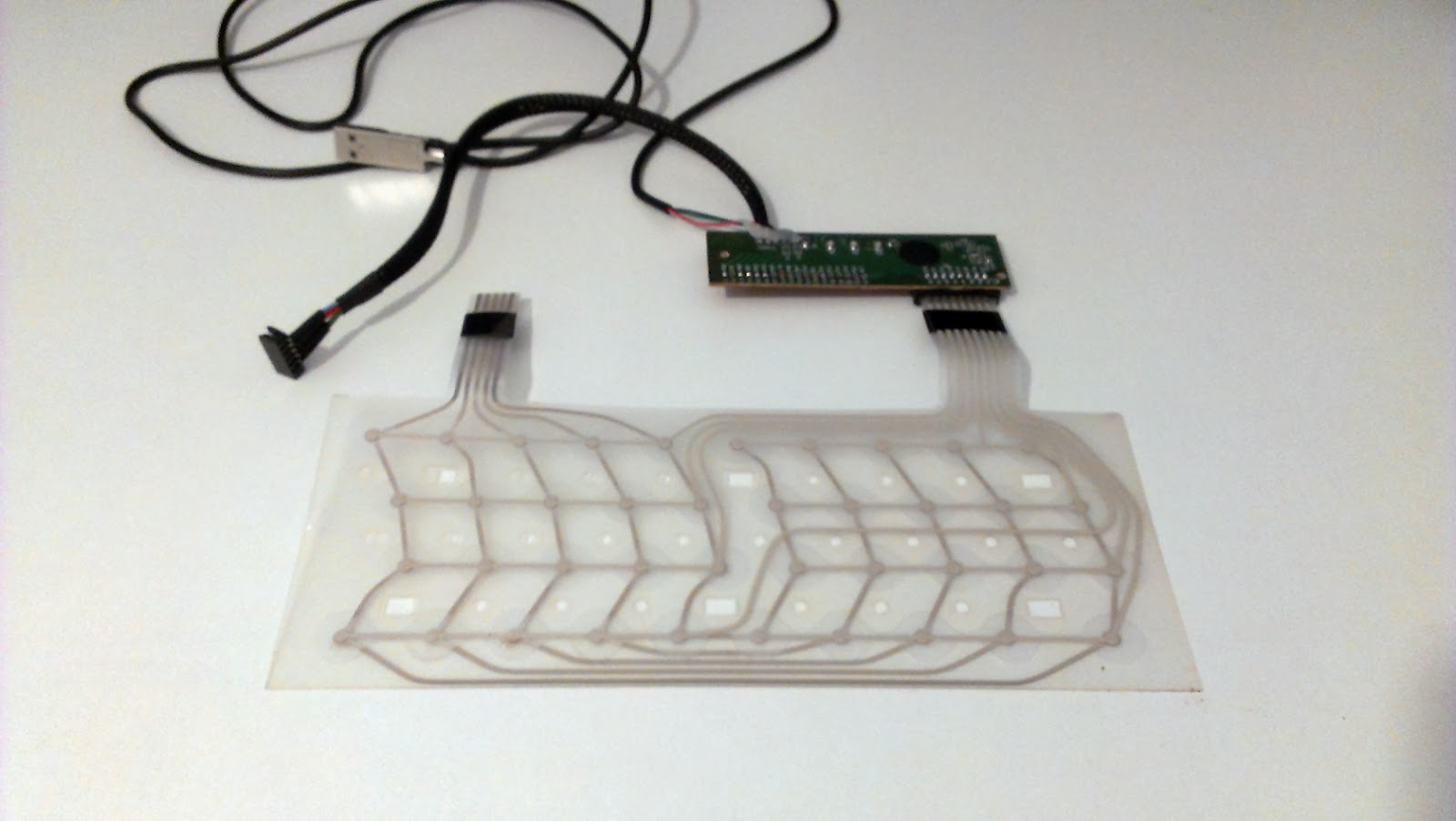

Getting the keyboard to work

I really wanted to integrate the Pi into the Spectrum, as opposed to the other way around, which consequently is quite difficult.

The keyboard membrane functions to short out two pins to generate the keystrokes. The Spectrum uses 5 and 8 pin connectors, therefore 5x8 = 40 key combinations are possible. The first job was to integrate the spectrum membrane into a USB keyboard which could be used with the Pi.

Once this was joined together a complete key-map can be determined by pressing the keys on the membrane and seeing what keystrokes are generated by the Pi and putting them into a spreadsheet for reference :

The greyed out keys are what the Spectrum keyboard 'should' print, the red keys are what actually prints on the screen. As can be seen the map is a complete mess, ??? denotes a function of the Japanese standard keyboard of all thing. No matter, all that is needed is the key codes from this reference.

When a key is pressed, the computer simply reads it as a code. For example key A may be code 65, B is code 66, C is code 67 and so on. All that needs to be done is tell the computer code 65 no longer means A, it means something else. It's a bit like taking the keys off the keyboard and rearranging them, but doing it on a software level.

This is where things get extremely tricky...

Everyone I have seen at this stage use a program on the Pi called xmodmap to fudge the keyboard. It has to be run as a script or manually on every boot and takes a long time for the Pi to compile, from what I have seen it also does not fully emulate the Spectrum's keyboard nor does it run in Linux's command line interface (shell). I wanted a more professional feel to my Spectrum Pi so I wanted to totally edit or create a key map so it worked on all levels.

This is a lot harder than it seems and there is scarce documentation on the subject requiring less than a computer degree to make sense of !

Firstly I tried to re-program the existing generic keyboard map the Pi uses, unfortunately this has no provision for a SHIFT + Function key and I need this to generate some capital letters and symbols. I also struggled to define some of the Japanese function keys stated above and it looked like this method not going to be possible as a lot of people had stated on forums.

However, not to be beaten, using another 'model' (eg the Commodore Amiga) of key maps allowed me to generate the functions I wanted. This is also handy as it still preserves the old generic model in case you want to go back to them later.

There are three files that need to be worked on here :

1) /usr/share/X11/xkb/keycodes

This is where the MODELS are stored. A model defines what code refers to what location on the keyboard. If this sounds complicated, that's because it is. For example, when a key is pressed code 23 may be generated, the MODEL file changes this code into an alias...in this case AD01.

2) /usr/share/X11/xkb/symbols

This is where the LAYOUTS are stored. A layout defines what alias (defined in the keycode file) makes what key to print on the screen. In the above example code 23 = AD01 = letter Q.

The idea is the model should be regarded as a type of keyboard, and the layout regarded as the region or language. The whole process is long winded and complicated, especially when you're working it out with no instructions !

It also has one last twist to the tale. The reason why people said it was impossible to re-map keyboards by editing these two files is because they missed a quirk in the last file...

3) /etc/default/keyboard

This file tells the Pi what model and layout to use. It is imperative to understand that if these values do not change in this file, then a new keyboard will NOT be compiled. People were editing the model and layout files and wondering why nothing had changed, believing it didn't work. However, by studying the Pi's startup process you could tell that when you changed the 'keyboard' file the Pi took longer to boot. This lead me to believe that in order to generate new keyboard maps the file names of the model and layout would have to be changed in the 'keyboard' file every time you made a change / edit.

This is indeed the case, the easy way was to make a re-named clone of the model and layout files and alternate between them when testing, that way the Pi would always re-generate the keyboard maps using your trial and error values each time.

Confused ??!!

I'd be annoyed if you weren't !

It's extremely hard for me to put this into words, it's long winded and a weird way of programming the keyboard if you ask me, BUT it does work. Through this you can generate the Spectrum ZX keyboard very accurately, it loads instantly and is widely customisable.

The keyboard membrane functions to short out two pins to generate the keystrokes. The Spectrum uses 5 and 8 pin connectors, therefore 5x8 = 40 key combinations are possible. The first job was to integrate the spectrum membrane into a USB keyboard which could be used with the Pi.

Once this was joined together a complete key-map can be determined by pressing the keys on the membrane and seeing what keystrokes are generated by the Pi and putting them into a spreadsheet for reference :

The greyed out keys are what the Spectrum keyboard 'should' print, the red keys are what actually prints on the screen. As can be seen the map is a complete mess, ??? denotes a function of the Japanese standard keyboard of all thing. No matter, all that is needed is the key codes from this reference.

When a key is pressed, the computer simply reads it as a code. For example key A may be code 65, B is code 66, C is code 67 and so on. All that needs to be done is tell the computer code 65 no longer means A, it means something else. It's a bit like taking the keys off the keyboard and rearranging them, but doing it on a software level.

This is where things get extremely tricky...

Everyone I have seen at this stage use a program on the Pi called xmodmap to fudge the keyboard. It has to be run as a script or manually on every boot and takes a long time for the Pi to compile, from what I have seen it also does not fully emulate the Spectrum's keyboard nor does it run in Linux's command line interface (shell). I wanted a more professional feel to my Spectrum Pi so I wanted to totally edit or create a key map so it worked on all levels.

This is a lot harder than it seems and there is scarce documentation on the subject requiring less than a computer degree to make sense of !

Firstly I tried to re-program the existing generic keyboard map the Pi uses, unfortunately this has no provision for a SHIFT + Function key and I need this to generate some capital letters and symbols. I also struggled to define some of the Japanese function keys stated above and it looked like this method not going to be possible as a lot of people had stated on forums.

However, not to be beaten, using another 'model' (eg the Commodore Amiga) of key maps allowed me to generate the functions I wanted. This is also handy as it still preserves the old generic model in case you want to go back to them later.

There are three files that need to be worked on here :

1) /usr/share/X11/xkb/keycodes

This is where the MODELS are stored. A model defines what code refers to what location on the keyboard. If this sounds complicated, that's because it is. For example, when a key is pressed code 23 may be generated, the MODEL file changes this code into an alias...in this case AD01.

2) /usr/share/X11/xkb/symbols

This is where the LAYOUTS are stored. A layout defines what alias (defined in the keycode file) makes what key to print on the screen. In the above example code 23 = AD01 = letter Q.

The idea is the model should be regarded as a type of keyboard, and the layout regarded as the region or language. The whole process is long winded and complicated, especially when you're working it out with no instructions !

It also has one last twist to the tale. The reason why people said it was impossible to re-map keyboards by editing these two files is because they missed a quirk in the last file...

3) /etc/default/keyboard

This file tells the Pi what model and layout to use. It is imperative to understand that if these values do not change in this file, then a new keyboard will NOT be compiled. People were editing the model and layout files and wondering why nothing had changed, believing it didn't work. However, by studying the Pi's startup process you could tell that when you changed the 'keyboard' file the Pi took longer to boot. This lead me to believe that in order to generate new keyboard maps the file names of the model and layout would have to be changed in the 'keyboard' file every time you made a change / edit.

This is indeed the case, the easy way was to make a re-named clone of the model and layout files and alternate between them when testing, that way the Pi would always re-generate the keyboard maps using your trial and error values each time.

Confused ??!!

I'd be annoyed if you weren't !

It's extremely hard for me to put this into words, it's long winded and a weird way of programming the keyboard if you ask me, BUT it does work. Through this you can generate the Spectrum ZX keyboard very accurately, it loads instantly and is widely customisable.

New Plumbing

After cutting a new inspection panel with the multi-tool I managed to damage the old copper pipework which had been laid directly under the floorboard join as opposed to in the centre line making damage almost inevitable.

Re-plubing and soldering this in copper neatly was to be expensive and arduous due to the cramped and poorly planned layout so I decided to try plastic heating pipe.

This is made by a company called Speedfit and it's very cheap and user friendly, I really like the ability to manipulate the joints after fitting - I would thoroughly recommend it.

I did have to do a few solder and compression joins but thankfully I could prepare them on the bench and then fit the pipes in place afterwards. Overalls it's a cracking job.

Re-plubing and soldering this in copper neatly was to be expensive and arduous due to the cramped and poorly planned layout so I decided to try plastic heating pipe.

This is made by a company called Speedfit and it's very cheap and user friendly, I really like the ability to manipulate the joints after fitting - I would thoroughly recommend it.

I did have to do a few solder and compression joins but thankfully I could prepare them on the bench and then fit the pipes in place afterwards. Overalls it's a cracking job.

Tuesday, 7 January 2014

Combination of New and Old

Generally speaking, I love the Raspberry Pi, however I do feel it has a few flaws I wanted to address. I wondered whether it could be combined with the retro classic Spectrum ZX, and after taking a second look it is remarkable how similar in concept the two machines are. Sir Clive Sinclair is one of my heroes and is quite apparent how far ahead of his time he really was with this marvel.

So the trick is, can the Spectrum ZX be retrofitted with a Raspberry Pi and still retain the characteristics of the best of both ?

First step was to get a decent donor Spectrum. This one on eBay was partially working for £30

Removing the lid exposes the fantastic plated through hole 80's technology ! I wanted to preserve the board for old times sake. The old RF modulator was bypassed so the unit could be viewed on a composite video before testing and setting aside for a rainy day.

Next to come off was the keyboard, the aluminium cover was gently removed and the distinctive rubber keys taken off the membrane. The membrane had to be trimmed back with scissors due to fractures in the tracks where it joins the PCB.

Due to the cut down, I had to use some black tape to keep the insulator part of the membrane attached to the conductive side, this makes it stronger and less likely the break in the future.

With all the bits off, it's now time to see how this is all going to work...

So the trick is, can the Spectrum ZX be retrofitted with a Raspberry Pi and still retain the characteristics of the best of both ?

First step was to get a decent donor Spectrum. This one on eBay was partially working for £30

Removing the lid exposes the fantastic plated through hole 80's technology ! I wanted to preserve the board for old times sake. The old RF modulator was bypassed so the unit could be viewed on a composite video before testing and setting aside for a rainy day.

Next to come off was the keyboard, the aluminium cover was gently removed and the distinctive rubber keys taken off the membrane. The membrane had to be trimmed back with scissors due to fractures in the tracks where it joins the PCB.

Due to the cut down, I had to use some black tape to keep the insulator part of the membrane attached to the conductive side, this makes it stronger and less likely the break in the future.

With all the bits off, it's now time to see how this is all going to work...

Subscribe to:

Comments (Atom)